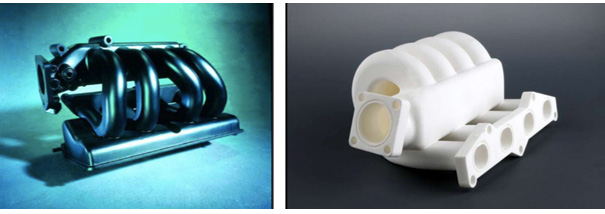

The inner side of auto engine intake pipe is composed with complex curved surface, which is very important for improving intake efficiency and burning fuel. During design process of engine intake pipe, it is necessary to make engine inlet port test for different intake pipe solution, the traditional method is to make dozens of cross sections as wooden mold of intake pipe or plaster mold of intake pipe by hand, and then cast a intake pipe by sand mold, however, due to the ability to understand drawing and skill level of wooden mold worker, it could cause deviation compared with the original design idea and drawing after the model is made , the deviation is very obviously sometimes. If use CNC technology to make model, it could better reflect design idea, but it take long time to prepare, especially for complex structure product. The Rover Company from British manufactured the external model and inner side model of engine intake pipe by taking SLS technology, and has satisfactory effect in practice.